Filling Systems of All Types

We offer many types of filling machines used to package a variety of products in today’s marketplace including liquids, pastes, chunky products, powders, granules, tablets, capsules, etc. Most filling machines are available from semi-automatic tabletop versions up to high-speed production line machines, including rotary fillers. Even within categories of filling machines, there are often many choices available, so we always encourage you to contact us to make sure you are buying the correct machine for your application.

3-in-1 Monoblock Washing Filling Capping Machine for Carbonated Drinks

The machine integrates three functions of bottle flushing, filing, and capping to achieve full automation, which can be applied to various bottle types. The whole machine adopts PLC computer program control and human-machine interface touchscreen buttons and is equipped with alarm devices for lack of caps and overload protection, which can detect and eliminate faults in time, and the degree of production automation is high. There are several models available to meet your specific needs, please contact us for a quote!

Auger Filler Hopper Refilling System

Save time and energy with an automatic powder auger feeding elevator! This product can be used in conjunction with powder-filling machines of various specifications and high-speed mixers so that powder and particles are automatically fed from the storage box by the screw (height can be custom) and added to your auger filler’s hopper by the level control. It has the characteristics of automatic feeding, fast feeding, labor saving, safety, and reliability.

Auger Filler

Auger Fillers are the machines of choice for all dry products that have the consistency of granule size and powders. In some cases, auger filling equipment can be used as a depositor for moist products such as cooked rice and pastes. The biggest advantage of auger-filling machinery is that the systems are relatively closed making auger fillers the ideal choice for very fine powders such as talc, flour, and baking soda which tend to get airborne with other systems. Auger fillers are also capable of relatively high fill rates compared with net weight fillers and take up less floor space.

Automatic Gravity Liquid Filling Machine

The gravity-filling machine is suitable for filling all kinds of water-based liquids in the food and drinking industry, like wine, milk, liquor, vinegar, juice, mineral water, etc. It can also fill liquid in the agricultural chemicals industry like liquid fertilizer, liquid pesticide, and liquid insecticide, etc. It is available with 6, 8, 10, 12, 14, 16, 18, and 20 fill heads, for reaching fill speeds between 3000-6000 bottles per hour, based on 500ml fills.

Includes:

Touch Screen and PLC Control

316L Stainless Steel Contact Parts

Hopper Level Sensor

Bottle Position Device

BUS-250FH Vertical Pneumatic Filling Machine with Heater and Blender

- By heating circulating water in the interlayer of the hopper, the machine indirectly heats the material to a constant temperature, and stirs the material to increase the material fluidity, reducing the viscosity of the material so that it can accurately fill material with high viscosity.

- Equipped with quick disassembly and assembly joint for easy cleaning.

- Adopts pneumatic control and good orientation, so the filling accuracy is very high, the highest accuracy can be controlled within ± 0.5%.

Includes:

Filling Speed 20-40 times/minute

Filling Precision: ± 0.5%

Filling Ranges: 5-60ml, 15-120ml, 60-250ml, 120-500ml, 250-1000ml, 500-2500ml, 500-5000ml

Air Pressure: 5-8 Mpa

Power: 220V, 4500W

Dimensions: 760x650x1650mm

Weight: 70KG

Automatic Peristaltic Pump Liquid Filling and Capping Machine

The SF-PEM is a Monoblock filling and capping machine (filling and capping machine together). All stations work on a star wheel which is suitable for small volume bottles. It is commonly used in tube, reagent testing tube, eye drop, e-liquids, essential oil biologic liquid, and some other small bottles and vials, with liquid inner cap pressing and our cap closing in pharmaceutical and other industries.

Includes:

Filling Range: 1-30ml (30-100ml is optional)

Cap Type: All kinds of screw caps/ press caps/ aluminum caps

Filling Method: Peristaltic Pump

Filling Speed: 60-3000 BPH (depends on number of fill heads and capping head)

Filling Precision: ± 0.5-1%

Power 220/380V, 50/60Hz, 15.Kw (custom to your requirements)

Air Pressure: 0.6-0.8 Mpa

Configuration Options:

1 Fill Head, 1 Capping Head

2 Fill Heads, 1 Capping Head

2 Fill Heads, 2 Capping Heads

4 Fill Heads, 2 Capping Heads

Check Valve Piston Filling Machines

Check Valve Piston Fillers are basically liquid-filling equipment with one-way valves that open and close by the force of the liquid (and maybe some light spring action). On the backstroke, the outlet valve is forced shut while the inlet valve is forced open. On the forward stroke (this fills the bottle) the opposite takes place. One advantage of this type of filler is that it can be self-priming on low-viscosity liquids. Piston filling is among the most accurate types of filling available since it displaces the same volume with every stroke. The limitations of check valve piston filling are that they only handle liquids to a light lotion consistency and will foul if there are any particulates in the solution.

Cup Filler

Cup Filler Systems are used for dispensing a variety of dry free-flowing products such as beans, rice, pet food, candy, seeds, and more without any product degradation. They’re an economical alternative for volumetric filling of free-flowing products. The concept is actually quite simple if you imagine dipping your measuring cup into a product and then leveling it with a straight-edged knife. This is the basic principle behind a cup-filling machine. The only difference is that the product flows from a hopper above and the knife is the edge of the hopper. For lower speed applications pocket fillers are often reciprocating devices. But higher speed cup filling equipment utilizes rotary systems that can be scaled up to match almost any speed requirement.

GI-3100 INLINE PRESSURE FILLER

Pressure Overflow Filling machines have their tanks below the bottom of the bottle. The tank flood feeds a pump (generally a centrifugal pump but also positive displacement pumps for thicker liquids) which then flows directly into the bottle until it reaches the fill level at which point excess product flows directly back into the tank. When filling plastic bottles the pump must be turned off (always for positive displacement pumps) before removing the filling tubes to allow the bottles to return to normal size (they swell under pressure) and drain off excess liquid. The big advantage of pressure fillers is that bottles fill more quickly so fewer heads (and space) are required and higher viscosity products can be filled. The disadvantage is that foamy products must be filled at slower pump speeds than normal, and this will work only if the foam settles out fairly quickly.

Common Features:

- 304 Stainless steel heavy-duty welded C frame.

- Color touch screen panel

- 7 Job memory

- 20-gallon stainless steel overflow tank.

- Stainless steel cover for overflow tank.

- 20 hose, 304 stainless steel feeding manifold.

- All contact parts are stainless steel, sanitary, Teflon, Viton, and hoses per your requirements.

- Special seals or hoses by order.

- Calibrated guide for fast height changeovers.

- Machine mounted on 4 heavy-duty casters.

- Leveling of machine by 1-inch 304 stainless steel leveling screws.

Peristaltic Liquid Dispensing Pump

A Peristaltic Pump works by placing tubing into the pump which then has rotating rollers that alternately squeeze and relax the tubing to force the liquid forward. This type of system works well in pharmaceutical environments or anywhere that you want absolutely no chance of cross-contamination. Simply throw away the tubing at the end of a run.

Rotary Valve Piston Filling Machines

Rotary Valve Piston Fillers are distinguished by the rotary valve which has a large throat opening to allow thick products and products with large particulates (up to 1/2″ diameter) from the supply hopper to flow through unimpeded. Great as a tabletop model or can be ganged for higher production requirements. Fill pastes, peanut butter, gear oil, potato salads, Italian dressing, and much more on this type of piston filler with the accuracy of plus or minus one-half percent. Fills accurately at a ten-to-one ratio of the cylinder set.

S-4 Net Weight Filler Standard

The Model S-4 Semi-Automatic Scale System is a great first step to take your business from hand scooping to automation. Your bulk product is placed in the supply hopper at the top of the machine. The S-4 uses an electromagnetic vibratory feeder to move the product from the supply hopper to the weigh hopper where it is weighed. When the target weight is reached, the Controller stops the feeder, and the weigh hopper opens automatically or with the foot switch to dump your product into your container. A new fill cycle is started and your filled bag may now be sealed.

Features:

- Self-adjusting Controller

- Reads out to 1 gram or .001 lb

- Controller range up to 10lbs.

- Supply Hopper capacity 3.5 cu.ft. (equivalent to 5five-gallon pails).

- Includes powder-coated chassis (stainless steel optional.)

- All product contact surfaces stainless steel

- Footprint 4.6 sq.ft., 68” high

- 120V 60Hz (wall outlet); (240V 50Hz optional)

- Handles any free-flowing dry bulk products

- Can be used with any bags or rigid containers

- Automatic tare adjustment

- Self-adjusting bulk & dribble speed control

- Up to 800 fills/hour

S-4 Net Weight Filler Tabletop

The Model S-4 Semi-Automatic Scale System Table Top Model is a great first step to take your business from hand scooping to automation. Your bulk product is placed in the supply hopper at the top of the machine. The S-4 uses an electromagnetic vibratory feeder to move the product from the supply hopper to the weigh hopper where it is weighed. When the target weight is reached, the Controller stops the feeder, and the weigh hopper opens automatically or with the foot switch to dump your product into your container. A new fill cycle is started and your filled bag may now be sealed.

Features:

- Self-adjusting SMART Logical Controller II

- Reads out to 1 gram or .001 lb

- Controller ranges up to 10 lbs.

- Supply Hopper capacity 3.5 cu.ft.(equivalent to 5 five-gallon pails).

- Includes powder-coated chassis(stainless steel optional.)

- All product contact surfaces stainless steel

- Footprint 4.6 sq.ft., 41.5” high

- 120V 60Hz (wall outlet); (240V 50Hz optional)

- Handles any free-flowing dry bulk products

- Can be used with any bag or rigid containers

- Automatic tare adjustment

- On-the-fly, self-adjusting bulk & dribble speed control

- Up to 800 fills/hour

S-5 Bulk Net Weight Filler

The very accurate and easy-to-operate Model S-5 Semi-Automatic Scale System has automatic tare, automatic feed and speed controls for both bulk and dribble feed rates and automatic set points. The product flow from the hopper to the feed pan can also be controlled by an adjustable slide gate.

Features:

- Bulk filling for weights of up to 50 lbs.

- Self-adjusting Controller

- Controlling reads out to 1 gram or .01 lbs.

- Scale range from 1 gram up to 50lbs.,

- Supply Hopper capacity 3.5 cu. ft. (equivalent to 5 five-gallon pails).

- Includes powder-coated chassis and table with a 23” range of height

- All product contact surfaces stainless steel

- Footprint 4.6sq.ft., 68” high

- 120V 60Hz (wall outlet); 240V 50Hz optional

- Handles any free-flowing dry bulk products

- Can be used with all bags or rigid containers

- Automatic tare adjustment

- Self-adjusting bulk & dribble speed control

- Up to 400 fills/hour

- Table height is adjustable to accommodate containers from 3” to 36” high.

- Scale Total Weight: 140lbs.

- Air Requirements: <0.25 cfm air supply at 30psi (only needed with optional Dribble Feed Gate)

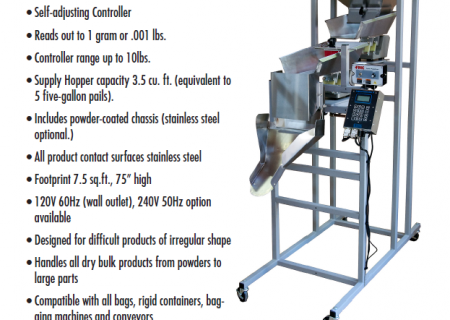

S-6 CASCADING NET WEIGHT FILLER

The Model S-6 Cascading Scale System is designed to fill harder-to-run products such as crackers, chips, wrapped products, and other non-free-flowing products. A very accurate and easy-to-use control system monitors the product depth in the lower pan allowing for consistent filling. The S-6 utilizes many of the same systems found on our S-4, including the Logical Controller II, for reliable, hassle-free operation.

Features:

- 2 Cascading feed pans

- Self-adjusting Controller

- Reads out to 1 gram or .001 lbs.

- Controller range up to 10 lbs.

- Supply Hopper capacity 3.5 cu. ft. (equivalent to 5 five-gallon pails).

- Includes powder-coated chassis (stainless steel optional.)

- All product contact surfaces stainless steel

- Footprint 7.5 sq.ft., 75” high, occupies only 23” x 48” of floor space

- 120V 60Hz (wall outlet), 240V 50Hz option available

- Designed for difficult products of irregular shape

- Handles all dry bulk products from powders to large parts

- Compatible with all bags, rigid containers, bagging machines, and conveyors

- Automatic tare adjustment

- Self-adjusting bulk & dribble speed control

- Up to 800 fills/hour

- Total scale weight: 240 lbs

- 5” Discharge Chute standard

- Air Requirements: <0.5 CFM air supply at 30 psi

S-7 DUAL LANE NET WEIGHT FILLER

The Model S-7 Dual Lane Scale System shares many of the same basic characteristics as the S-4. A very accurate and easy-to-use Logical Controller II allows for three different modes of operation. In a simultaneous dump, the scale fills both weigh hoppers at the same time, allowing for twice as much product flow as our S-4. In an individual dump, the scale dumps whichever weigh hopper is at weight. This gives twice the speed of our S-4 machine. Finally, the Model S-7 can mix products with the optional divided supply hopper. The S-7 Dual Logical Controller II system can be set to weigh two completely different products at different weights to easily mix products into one container.

Features:

- Two lanes for twice the speed

- Self-adjusting Controller

- Reads out to 1 gram or .001 lb

- Controller range up to 10 lbs. per lane

- Supply Hopper capacity 5.1 cu. ft. (equivalent to 7 five-gallon pails).

- Includes powder-coated chassis (stainless steel optional)

- All product contact surfaces stainless steel

- Footprint 7.5 sq ft, 68” high

- 120V 60Hz (wall outlet), 240V 50Hz option available

- Handles all free-flowing dry bulk products

- Compatible with all bags, rigid containers, bagging machines, and conveyors

- Automatic tare adjustment

- Self-adjusting bulk & dribble speed control

- Up to 1500 fills/hour

- Overall height: 5’8” (68”), occupies only 30”x35” of floor space

- Supply Hopper capacity: 5.1 cu. ft. (equivalent to 7 five-gallon pails)

- Scale total weight: 225 lbs.

- Standard funnel discharge opening is 2.5” x 2.5” square

- Power requirements: 4 amps, 120 volts 60Hz AC

- Air Requirements: <1 CFM air supply at 30 psi

SAF-300 Semi-Automatic TABLETOP Auger Powder Filler

The SAF-300 Semi-automatic Tabletop Auger Powder Filling Machine with PLC + Touch Screen Control can work independently. Precise and innovative design makes the SAF-300 an economical and reliable packaging machine. It is the best choice for operator convenience! All of the hoppers of our auger filler were designed vertical/horizontal half-open type that make it easier to disassemble for cleaning.

Features:

- Semi-automatic Auger Filler

- Hopper Volume: 14L

- Total Power: 0.87KW

- Dosing Range: ≤100g

- Packing Speed: 25-35 bags/min

- Metering Accuracy: ±0.3-1% (Varies according to packing weight, speed, and product features)

Servo motor to control auger - Full stainless steel 304 hopper

- Vertical half-open hopper, easier disassembly for cleaning

- Material contact part is polished skill

- Quick-remove auger

Options:

Extra Auger Tooling

Spinner Plate

SUS316 Contact Parts

Dust Collection Device (200W)

Loadcell

Semi-Automatic Auger Filler

All of our Semi-automatic Auger Fillers can be easily automated by adding conveyors or modified for mounting on form and fill machines. All of the machines include a stirring bar to keep the product constantly fed to the fill auger. They are available in small doses (1-50g, 10-200g) and medium doses (10-500g, 10-1000g, and 100-5000g). The biggest advantage of auger-filling machinery is that the systems are relatively closed making auger fillers the ideal choice for very fine powders such as talc, flour, and baking soda which tend to get airborne with other systems. Auger fillers are also capable of relatively high fill rates compared with net-weight fillers and take up less floor space.

Siphon Filler

The 5 Station J1 Siphon Filler offers a very economical system for small through medium volume production filling of glass, plastic, or metal containers from 2 ounces through 1 gallon (and up to 2 gallons depending upon the dimensions of the container) of most low viscosity liquids. The filler consists of a rectangular trough or tank with a float-controlled valve to maintain the uniform level of the liquid in the tank. The filler is mounted on legs for convenient operating height, and it is supplied with a bottle holder rack, a drip tray, spouts, a siphon starter, and other accessories and fittings as required. The spouts consist of specially designed tubular goosenecks mounted on brackets, which serve as fulcrums; nozzles consisting of double tube assemblies are attached to the goosenecks. The outer tube of the nozzle has a weighted drop or bottle stop which serves as the contact area for the bottle or other container to be filled; when the outer tube is raised by the bottle, it exposes an opening on the inner tube permitting the liquid to flow into the bottle; when the bottle is removed, the weighted drop brings the outer tube down against a valve seat on the inner tube, thereby shutting off the flow before the bottle is completely removed from the spout.

Machine includes:

Tank 304S/S

Drip Pan 304S/S

Tank Float Valve Assembly 316S/S

1″ Inlet With Ball valve 316S/S

Float Ball Polypropylene for Inlet Assembly

Siphon Starter with Vinyl Bulb

(5) Saddle Assemblies

(5) Complete Spouts – Gooseneck and Nozzle, in 3/8”, 1/2”, 5/8”, or 3/4″

Mill Steel Painted Stand (stainless steel stand or casters are optional)

Options:

Special Longer Spouts – 12” and 14” Long

Special Longer Nozzles – 12” and 14” Long

Hooded Cover with Open Front

Special Gaskets – Neoprene, EPDM, Buna, Viton, Teflon