Your Trusted Partner for Complete Packaging Machinery Solutions

Busch Machinery has been in Business Since 1983

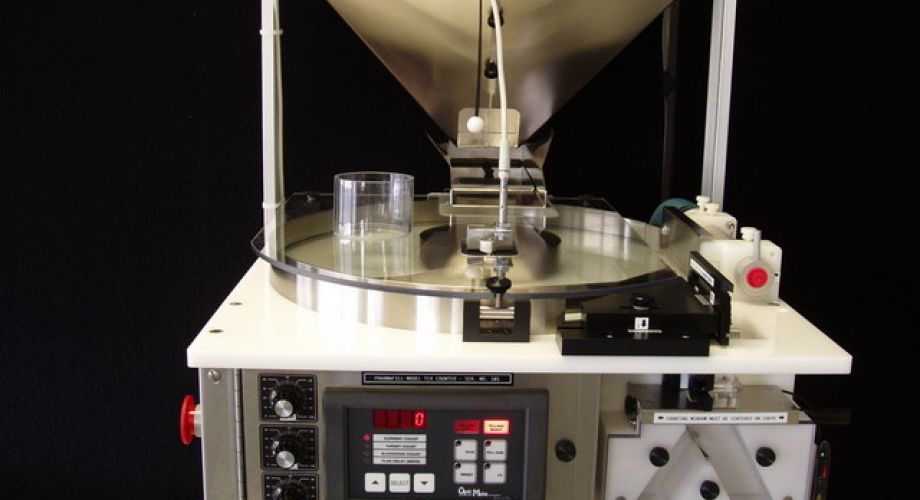

In business for over 40 years, Busch Machinery is your single source supplier of a full range of packaging machinery and systems including: filling machines, labeling equipment, capping machines, bottling equipment, flexible packaging systems, shrink wrap machines, tablet and pill counters, and complete packaging lines for the Chemical, Pharmaceutical, Cosmetic, Food and Beverage industries and much more!.

More packaging equipment is available also, such as, bottle unscramblers, bottle rinsers, liquid fillers, labelers, cappers, sleeving machines, horizontal flow wrappers, vertical form, fill, and seal machines, label applicators, cartoning machines, desiccant inserters, powder fillers, tube filling and sealing machinery, conveyors, heat tunnels, turntables, inkjet coders, printers and complete turnkey packaging systems. Additionally, Busch Machinery also has a wide array of End-of-Line Packaging Equipment, including case erectors, case sealers, case packers, palletizers, direct case coders and printers, and stretch wrapping machines.

Whether your company is a small startup operation looking for a semi-automatic packaging machine or a large operation needing high-speed packaging equipment, Busch Machinery can offer the right machinery for the job based on over 40 years of actual hands-on applications expertise in the packaging machinery and equipment field. Customer service is our watchword. Call us at any time: 520-777-3360 or toll-free in the USA at 800-840-9573.