Labeling Machines & Printers For All Kinds of Products

Labeling machines come in numerous configurations dependent on the type of packaging that needs to be labeled. Busch Machinery offers many choices such as top labeling, bottom labeling, wrap labeling, front and back labeling, print and apply labeling, syringe labeling, ampoule labeling, vial labeling and sleeve applicators in models ranging from benchtop semi-automatic labelers to high speed automatic labeling systems. Among the types of labelers we have available are pressure sensitive labelers, hot melt glue labeling machines, cold glue labelers and shrink sleeve labelers (also known as full body sleevers). No one else can offer you the number of selections of labeling machinery as Busch Machinery with its expertise in the labeling equipment field, in many cases allowing you to choose from several selections to match your budget and needs.

We offer customized solutions for all labeling applications, we will build you the best labeler for your product!

BM-KTN-SYR Semi-Automatic Syringe Labeler

- High-Efficiency Double Station Labeling Machine

- Label Syringes and Other Unstable Products Like Lipstick, Markers, Ampoules, etc.

- Product Is Labeled in One Station While Another One Is Free for Placing a New Product

- Accurate Positioning and Alignment of Labels

- Variable Speed – Around 40 PPM

- Foot Switch or Automatic Activation

- OPTIONAL: Pneumatic Unloading Device (Pusher)

- 110VAC Unless 220VAC is Requested

- Size: 1200x900x1400mm

- Weight: 200Kg

BM-K50 Compact Label Applicator

- Reversible from Left to Right Configuration and Vice Versa

- Internal Memory Saves Up to 50 Label Formats

- Numeric Keypad with LCD Display

- Mounting Arm for Easy Installation and Orientation

- See Full Image for More Information

BM-K50 Label Applicator

- Reversible from Left to Right Configuration and Vice Versa

- Internal Memory Saves Up to 50 Label Formats

- Numeric Keypad with LCD Display

- Mounting Arm for Easy Installation and Orientation

- Ready for External Printer Use

- See Full Image for More Information

BM-K200 Compact Label Applicator

- Reversible from Left to Right Configuration and Vice Versa

- Internal Memory Saves Up to 50 Label Formats

- Numeric Keypad with LCD Display

- Mounting Arm for Easy Installation and Orientation

- Ready for External Printer Use

- See Full Image for More Information

BM-K200 Label Applicator

- Reversible from Left to Right Configuration and Vice Versa

- Internal Memory Saves Up to 50 Label Formats

- Numeric Keypad with LCD Display

- Mounting Arm for Easy Installation and Orientation

- Ready for External Printer Use

- See Full Image for More Information

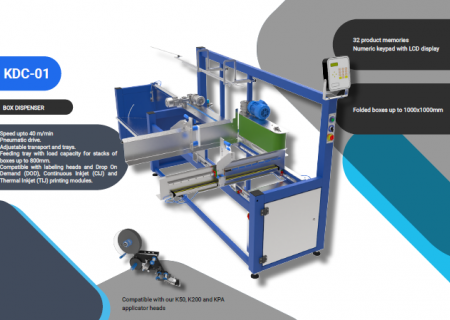

BM-KDC-01 Box Dispenser

- 32 Product Memories

- Numeric Keypad with LCD Display

- Folded Boxes Up to 1000x1000mm

- Pneumatic Drive

- Adjustable Transport and Trays

- Compatible with Our K50, K200 and KPA Applicator Heads

- See Full Image for More Information

BM-KFLEX K200 Label Applicator with TTO Printer

- Reversible from Left to Right Configuration and Vice Versa

- Internal Memory Saves Up to 50 Label Formats

- Numeric Keypad with LCD Display

- Mounting Arm for Easy Installation and Orientation

- See Full Image for More Information

BM-KFLEX Label Applicator with TTO Printer

- Reversible from Left to Right Configuration and Vice Versa

- Internal Memory Saves Up to 50 Label Formats

- Numeric Keypad with LCD Display

- Mounting Arm for Easy Installation and Orientation

- See Full Image for More Information

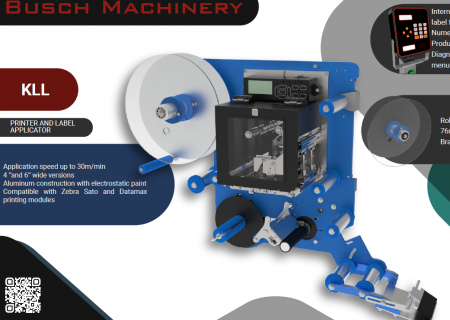

BM-KLL Printer and Label Applicator

- Left or Right Version

- 4” and 6” Wide Versions

- Internal Memory Saves Up to 50 Label Formats

- Numeric Keypad with LCD Display

- Product Counter

- See Full Image for More Information

BM-KPA Printer and Label Applicator

- Internal Memory Saves Up to 50 Label Formats

- Numeric Keypad with LCD Display

- Product Counter

- Built In Aluminum with Electrostatic Paint

- IEEE 1284 Bidirectional Parallel Port

- 232/422/485 Serial Port and Ethernet Port (Optional)

- See Full Image for More Information

BM-KTL Top Labeler

- 32 Product Memories

- Numeric Keypad with LCD Display

- Variable Speed Conveyor, Adjustable Side Guides

- Speed Up To 30M/min

- Different Label Head Options (BM-K50, BM-K200)

- Custom Transport Width

- Built In Stainless Steel

- See Full Image for More Information

BM-LCW Wrap Labeler

- Roller Wrapping Labeling System

- 32 Product Memories

- Numeric Keypad with LCD Display

- Variable Speed Conveyor, Adjustable Side Guides

- Multiple Labels On a Single Container

- See Full Image for More Information

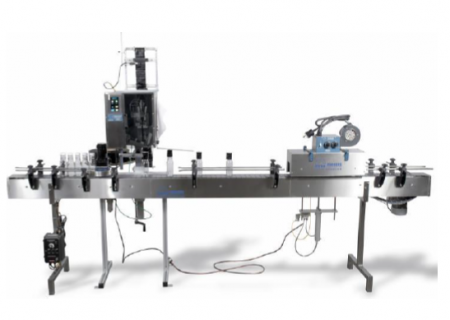

BM-MS-100 Front Back and Wrap Labeler

- Front and Back Labeling System with Wrapping

- 32 Product Memories

- Numeric Keypad with LCD Display

- Variable Speed Conveyor, Adjustable Side Guides

- Band or 3 Roller Wrapping for Round Product Labeling

- Chain Aligner or Servo Pneumatic Aligner System

- Speed Up to 120 PPM

- See Full Image for More Information

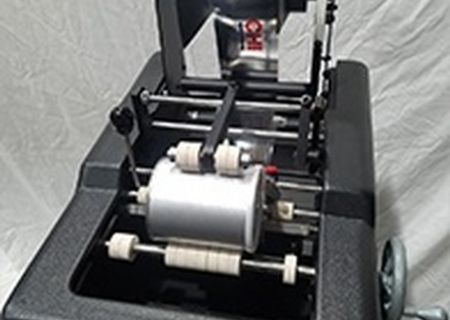

BM-UW Unstable Wrap Labeler

- Unstable Cylindrical Labeling System

- 32 Product Memories

- Numeric Keypad with LCD Display

- Variable Speed Conveyor with Automatic Synchronization

- Wrap Roller

- Containers from 9.5 to 50mm in Diameter

- Speed Up to 150 PPM

- See Full Image for More Information

BM-ELF-50 Automatic Tabletop Wrap Labeler

- Portable Wrap Around Labeler for Cylindrical Products

- Easily Adjustable Sensors for Various Labels

- Production Preset Function

- 5 Product Memories

- User Friendly Operating Interface

- Max Dispensing Speed 52.5ft/min

- Max Label Size 4.75”x11.8”

- 110/220VAC, 50/60Hz, 1P

- Dimensions (LWH) 43.3×34.3×20”

- Weight 165 lbs.

BM-ELF-20 Automatic Tabletop Top Labeler

- Portable Top Labeler

- Easily Adjustable Sensors for Various Labels

- Production Preset Function

- 5 Product Memories

- User Friendly Operating Interface

- Max Dispensing Speed 16M/min

- Max Label Size 120mmx300mm

- Max Container Width 150mm

- Max Container Height Flt 120mm

- Max Conveyor Width 160mm

- 110/120VAC, 50/60Hz, 1P

- Dimensions (LWH) 1100x531x734mm

- Weight 60 Kg

BMADL-200 Hotmelt Wrap Labeler with Wheeled Cart

- Applies Labels to Round Containers from One Ounce to One Gallon

- Applies Glue to the Ends of the Label or the Whole Label

- Automatically Adjust Glue Pattern

- Automatic Label Feed via Large Capacity Label Hopper (300 Labels)

- Fast Container Change with No Change Parts Necessary

- Speed 20 to 40 Containers Per Minute

- Machine Stand with Casters

- Container Diameter 1” to 12”

- Minimum Label Size (W x L) 3/4″ x 4”

- Maximum Label Size (W x L) 8.5” x 25”

- 110VAC, 60Hz, 10a (220VAC Optional)

- Dimensions (LWH) 66” x 20” x 36”

BMADL-205 Hotmelt Wrap Labeler for Pails with Wheeled Cart

- 5 Gallon Pail Labeler with Automatic Lug Registration

- Applies Glue to the Ends of the Label or the Whole Label

- Automatically Adjust Glue Pattern

- Automatic Label Feed via Large Capacity Label Hopper (300 Labels)

- Fast Container Change with No Change Parts Necessary

- Speed 20 to 40 Containers Per Minute

- Machine Stand with Casters

- Container Diameter 3” to 12”

- Minimum Label Size (W x L) 3/4″ x 4”

- Maximum Label Size (W x L) 8.5” x 25”

- 110VAC, 60Hz, 10a (220VAC Optional)

- Dimensions (LWH) 66” x 20” x 36”

BMADL-300 Semi-Automatic Wrap Labeler with Wheeled Cart

- Pressure Sensitive Wrap Labeling Machine

- Applies Labels to Round Containers from One Ounce to One Gallon

- Labels 20 to 40 Containers Per Minute

- Fast Container Change with No Change Parts Necessary

- Machine Stand with Casters

- Container Diameter 3/4” to 12”

- Minimum Label Size (W x L) 3/4″ x 1”

- Maximum Label Size (W x L) 8” x 20”

- 110VAC, 60Hz, 5a (220VAC Optional)

- Dimensions (LWH) 26” x 20” x 36”

BMADL-301 Hand Crank Wrap Labeler No Cart

- Pressure Sensitive Manual (Hand Crank) Labeler

- Container Diameter 1” to 12”

- Minimum Label Size (W x L) 3/4″ x 1”

- Maximum Label Size (W x L) 8” x 20”

- Requires No Electricity

BMADL-302 Semi-Automatic Wrap Labeler No Cart

- Pressure Sensitive Wrap Labeling Machine

- Hand Trigger

- Automatic Brake Arm

- Fast Container Change with No Change Parts Necessary

- Labels Up to 25 Containers Per Minute

- Container Diameter 1” to 12”

- Minimum Label Size (W x L) 3/4″ x 1”

- Maximum Label Size (W x L) 8” x 20”

- 1110VAC, 60Hz

- No Stand

BMADL-310 Semi-Automatic Push Thru Wrap Labeler with Wheeled Cart

- Pressure Sensitive Wrap Labeling Machine

- Applies Labels to Round Containers from One Ounce to One Gallon

- Containers Manually Fed, Automatically Ejected

- Labels 30 to 50 Containers Per Minute

- Fast Container Change with No Change Parts Necessary

- Machine Stand With Casters

- Container Diameter 1/2″ to 12”

- Minimum Label Size (W x L) 3/4″ x 1”

- Maximum Label Size (W x L) 8” x 20”

- 110VAC, 60Hz, 6a (220VAC Optional)

BM6 Shrink Sleeve Neck Bander and Heat Tunnel

- Bands Up to 70mm Closure

- Larger Banding Sizes Are Available

- Speeds Up to 200 Units Per Minute

- Optional Dual Head Station Increases Output

- Cuts and Places PVC Roll Stock Bands Up to 6” Long

- Durable Stainless Steel Construction

- Quick Wash Down

- Compact Space-Saving Design

- Easy to Use and Maintain

VideoJet Ink Jet and TTO Printers

Ink jet coders are used for many different coding and printing operations. There are two basic types of inkjet coders; small character ink jet coders used for marking bottles with expiration dates and/or batch or lot numbers and large character inkjet printers generally used to print product information on boxes. We offer a wide range of OEM Coding Solutions from continuous inkjet printers to thermal inkjet printers and ribbon date coders. With a Wide-Range Option List for your 1D, 2D, Image, or Alpha-Numeric Characters of many sizes and combinations we are ready to handle your needs!