Other Machines and Accessories

Busch Machinery offers a variety of other machines including but not limited to: form fill and seal machines, capping machines, induction sealers, accumulation and infeed tables and conveyors, roller and motorized conveyors, incline and Z-conveyors, stretch wrappers, cotton inserters, desiccant inserters, L-sealers, heat shrink tunnels, metal detectors, bag sealing machines, bottle unscramblers, bottle and can cleaners, neck banders, ROPP cappers, lidders, auger and vacuum transfer systems, filling lines, tablet lines, carbonated beverage lines and water bottle lines. If you don’t see the machine you need, just give us a call or email us and we’ll find it for you!

Vertical Form Fill and Seal Machine

Busch Machinery offers a full line of Vertical Form Fill and Seal machines, also known as VFFS, plus sachet forming machines, stick-pack machines, pillow-pack machines, stand-up pouch filling and sealing equipment, and band sealers for small production with preformed bags. Most of us are aware of the typical vertical form fill and seal bags from our experience with snack foods. This type of bag is seen in potato chip packaging with a top and bottom seal and a long fin seal down the back side. We often refer to this kind of bag making and filling as a pillow pack. Aside from gusseted bag options, this pretty much defines what can be done with VFFS packaging machines insofar as larger bag sizes are concerned. However, what is less known to many would-be buyers is that vertical form-fill and seal machines can make 3 and 4 sided sealed pouches in bag sizes as large as 6 inches wide by 8 inches long, identical in appearance to what can be done on very expensive “Bartelt” type horizontal pouch making, filling and sealing machines for a lot less money. Furthermore, not only is it possible to make 4 side sealed pouches, but it is also possible to make twin packs, each with different ingredients. Small machines for individual pouches to a maximum of 3-3/8″ wide x 4-3/4″ long are called Sachet machines and can also do any of the three types of seals. Another type of Vertical Form Fill and Seal machinery is what is known as a “Stick” packer. Typically stick packs refer to long narrow packages that can be made for 1 – 10 at a time from a single web where the machine slits the web prior to forming. Stick packs will also have a fin seal or alternatively an envelope seal on the side. But the fact is that a stick packer VFFS packaging machine need not necessarily produce only a narrow package but can produce almost any sized bags within the limits of the web width handling capabilities of the particular machine. For instance, a 10-lane stick packer could easily be a 4-lane stick packer, with more than double the width bags. In reality, the best name for a “stick packer” is a multi-lane Vertical, Form, Fill, and Seal Machine. All of the VFFS packaging machines can be used to fill liquids, pastes, granules, powders, tablets, snack foods, small parts, and much more.

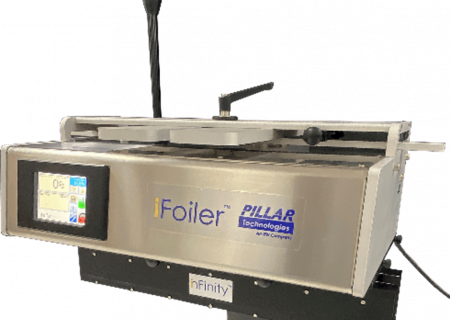

iFOILER INDUCTION SEALER

The iFoiler Induction Sealer features a highly functional touchscreen interface and multiple language functions. Extra functions integrated into the microprocessor, such as memory functions to save power settings and conveyor speeds, make the iFoiler simple to use and efficient and ensure better quality. Induction sealing technology lets you rapidly apply high-quality, durable seals to your products. This is accomplished by applying an electromagnetic field to a special induction seal inside your product cap. Induction sealing can be used for various products in categories like food and beverage, chemical, pharmaceutical, and much more. Induction sealing provides several benefits. It creates a reliable, powerful seal that prevents spills and preserves freshness by preventing air and moisture intrusion. You cannot reapply induction seal caps without an induction sealer, so they also provide tamper evidence to your products.

Accumulation Conveyor 1

Our custom-built Accumulation Conveyors are a safe and efficient alternative to the normal accumulation table that goes at the end of your labeling machine to collect product. They can be made in different lengths to suit your needs. This accumulation conveyor is made of three or more (upon request) chain conveyors.

The main advantages compared to the round tables are:

- There are no transfers (where products can fall) between the labeling machine conveyor and the accumulation table.

- All the products go to the side making it easier for the operator to reach them, in a round table they all go to the center making it harder to reach the products.

- It covers a bigger area of accumulation. With the round tables, there are side rails pushing everything to the center and leaving the perimeter free.

Accumulation Conveyor 2

Our custom-built Accumulation Conveyors are a safe and efficient alternative to the normal accumulation table that goes at the end of your labeling machine to collect product. They can be made in different lengths to suit your needs. This accumulation conveyor is made of three or more (upon request) chain conveyors.

The main advantages compared to the round tables are:

- There are no transfers (where products can fall) between the labeling machine conveyor and the accumulation table.

- All the products go to the side making it easier for the operator to reach them, in a round table they all go to the center making it harder to reach the products.

- It covers a bigger area of accumulation. With the round tables, there are side rails pushing everything to the center and leaving the perimeter free.

Automatic 4 Wheel Capping Machine with Cap Sorter

The BMSC4 Automatic Capping Machine is used to close all kinds of screw caps. It uses a cap vibrating sorter to feed caps to the bottle mouth. Then 4 wheels move together to close the caps. It is widely used for all kinds of bottles and caps with different materials in pharmaceutical, pesticide, chemical, food, cosmetics, and other industries.

Parameters:

Capacity: 40-60 Bottles/Min (pick & place), 50-80 Bottles/Min (cap pulling)

Bottle Diameter: 35-140mm

Bottle Height: 38-350mm

Cap Diameter: 25-70mm

Power: 380VAC, 50-60Hz, 3P, 1.2KW (optional 220VAC 1P)

Material: SUS304

Automatic 6 Wheel Capping Machine with Cap Elevator

The BMSC-6 Automatic Capping Machine is used to close all kinds of screw caps. It uses a cap elevator to feed caps to the bottle mouth. Then each side 3 wheels close the caps. It is widely used for all kinds of bottles and caps with different materials in pharmaceutical, pesticide, chemical, food, cosmetics, and other industries.

Parameters:

Capacity: 60-120 Bottles/Min

Bottle Diameter: 35-200mm

Bottle Height: 38-350mm

Cap Diameter: 25-140mm

Power: 380VAC, 50-60Hz, 3P, 1.2KW (optional 220VAC 1P)

Material: SUS304

Automatic Inline Waterfall Style Capping Machine

Our line of TruCap Inline Screw Cappers consist of two components: the base cap tightening unit and the cap sorting system with chute. When integrated together it becomes an automatic capper. Waterfall feeders are by far the most popular feeders for our automatic cappers because they serve as both sorter and cap elevator. With a floor-level hopper to load caps from bulk, it is very easy to work with. However, it is designed to work primarily with flat caps and depends on the closed end of the cap to be heavier than the rest of the cap, which is not the case with all caps. If there is any doubt, we should test your caps to make sure they will run.

Common Tightener Features:

Heavy-duty 304 stainless-steel welded C frame for easy mounting over existing conveyors

Heavy-duty linear carriage system for height adjustability

All shafts and threaded rods manufactured in 304 stainless-steel

Heavy-duty casters standard

No change of parts is needed for a wide range of containers

Front covers with safety interlock switches standard

Top driven to ensure no product spillage into drive assembly

Adjustable height to accommodate containers from 1 inch to 14 inches tall (Optional power height adjustment).

Common Waterfall Feeder Features:

Construction in stainless steel

18-inch-wide belt

Cap feeder is adjustable for bottle caps from 8mm to 110mm in diameter, via quick adjust knobs

Caps feed on demand, controlled by a photoelectric sensor

Air shutoff valve controlled by photoelectric sensor

Includes air regulator and filter

Feeder inclination adjustable from 0 to 5 degrees

Complete height adjustment by structure 1-inch bolts and/or cap delivery system

10 cubic foot cap hopper

Drive provided by DC gear motor

Independent Speed Control (potentiometer)

Electric and Pneumatic Requirements:

220 Volts, Single phase, 50/60Hz, 15 Amps

10 CFM @ 80 p.s.i.

BMCS1 Cotton Inserter

The BMCS1 cotton inserter automatically separates cotton, rayon, and polyester from continuous rolls into individual pieces and inserts them into the center of bottles or other containers at speeds of up to 80 bottles per minute. It packs proprietary, sensor-driven technology from the highspeed CS10 model into a compact design that enables growing companies to upgrade from manual to automated and start enjoying faster, easier, more dependable production without compromising the budget.

- Small footprint just 26.5” wide x 23” deep

- Height-adjustable from 54.5” – 64.5” high

- No-knife design safely separates cotton from coil

- Inserts from 1 – 9 pieces per bottle

- Piece length from 2”– 9”

- 50 – 80 pieces per minute

- Bottle heights 1”– 9”

Fantom Robot Stretch Wrapper

The Fantom Robot Self-Propelled Stretch Wrap System gives you the flexibility to wrap loads anywhere in your facility without sacrificing consistency and film savings. The semi-automatic controls make wrapping varying sized loads simple and easy. The Fantom Robot’s mobile design allows it to be brought to unstable loads, preventing the need to move them unwrapped. The self-propelled load tracking design means that products of any weight, length, or width can be wrapped simply. The Fantom Robot’s Select Stretch feature is located on top of the carriage and allows the operator to quickly change the stretch percentage between 230% and 270%. Automatically cutting the film at the end of the wrap cycle improves productivity by up to 30%. The on-board battery pack allows you to wrap 200-300 loads on a single charge, enough to run all day in most applications. A 4-battery upgrade is available to double output. Once your pallets are set up with your desired wrap pattern, those settings will reside in a section that requires a password to change. The operator gets access through pushbuttons and selectors for start and stop operations and basic front panel operations. This allows for consistency in wrapping from pallet to pallet. The front panel also features a Battery Gauge, so operators have a visual indicator of power status and when a battery charge is required. The system also includes 3 programmable wrap patterns.

Gravity Roller Conveyor

A Gravity Roller Conveyor lets a product move on rollers using the force of gravity to move the load. Gravity conveyors are one of the simplest and most affordable types of material handling systems. They work by allowing the product to roll along the upper surface. When mounted on a slight decline the parts begin moving across the rollers. They are great for warehouses, production facilities, or distribution centers. Most rollers for these conveyor systems are 1.5 inches to 1.9 inches in diameter. For extreme-duty applications, 2.5 inch and 3.5 inch diameters are available. Because they are light, you can use them for either temporary or permanent situations. Permanent floor supports or temporary tripod-style stands are also available. You can use roller curve units for corners.

Heat Shrink Tunnel

The Heat Shrink Tunnel is mainly used to shrink tamper evident poly film neck bands or labels of products in bottle shape, can shape, or barrel shape for glass bottles, plastic bottles, or paper cups. With the band or label either on the top, in the middle, at the bottom of the bottle, or wrapping the whole bottle, it is able to be shrunk with different types of models. The most common type of heat shrink tunnel is the electric heat tunnel. We also offer steam shrink tunnels. They are widely used in the food, medicine, cosmetic, and pesticide industries, etc.

Some Typical Features:

Product Size: 200mmW x 100mmH

Dimensions of Shrinkage Furnace (L,W,H): 1200x400x200mm

Conveying Material: Chain Stick

Conveying Speed: 0-15M/min

Transport Load Max: 10Kg

Machine Dimensions: 1600x560x660mm

Horizontal Metal Detector

The BM-G3012 Horizontal Metal Detector adopts advanced digital processing technology and can detect both magnetic and nonmagnetic metals in the product. It features a colorful touch screen that is convenient for communication between the operator and computer, high detecting sensitivity and stability, and multiple rejecting devices to choose from.

Features:

Model BM-G3012

Power Requirement: 220V/180W/50/60Hz/0.8A

Gross Weight: 200kg

Max package size (Width): 300mm

Max package size (Height): 120mm

Sensitivity (Fe): 0.8mm

Sensitivity (SUS): 1.5mm

Speed (m/min): 30m/min

Incline Conveyor

The Incline Conveyor is for lifting material to the hopper of your weigh scale or auger filler, etc.

Features:

Chain plate type: suitable for large particles of material conveying

Belt type: suitable for a wide range of free-flowing products.

Max conveying capacity: 5m3/h

Conveyor height: 2000-3600mm (customizable)

BM-5 Shrink Sleeve Neck Banding Machine

Neck Banding Machines are known as shrink sleeving machines, shrink banders, tamper-evident banders, neck banders, and, as some machines are capable of both, full body sleeves or shrink labels. No matter what the name, neck banders convert lay flat tube roll stock into a shrink band by opening and re-creasing the tube stock so that it opens more easily. The tube stock is then drawn back flat 90 degrees to its original position through the drive rollers and then is cut in any of several ways. Some neck banding machines cut after the film has been forced over the product by a V knife. Other shrink band applicators may cut while the stock is still flat while being held by vacuum cups, and our high-speed machines use a group of circular cutters located outside the mandrel after the band has been fed onto the product. Circular cutters work so fast that speeds of over 250 bottles per minute are possible on a single head.

Features:

Durable Stainless-Steel Construction

Quick Wash Down

Compact Space-Saving Design

Speeds Around 100 Bottles/Min

M5 Series Size Range 25-90mm Lay Flat

Band Lengths to 3”

Fast Changeover

Spacing Wheel for More Efficient Bottle Handling

BM-6 Shrink Sleeve Neck Bander and Heat Tunnel

The BM-6 is an excellent choice for an entry-level Shrink Labeling and Shrink Band Machine. The simplicity of design, user-friendly interface, and ease of use make it simple for line personnel to understand and operate. Using a spacing wheel instead of traditional feed-screw product transport mechanisms, changeover takes less than 10 minutes, thereby increasing output and efficiency. Once you’ve enjoyed the increased output & efficiency, you’ll understand why hundreds of companies have chosen the M6.

Features:

Durable Stainless-Steel Construction

Quick Wash Down

Compact Space-Saving Design

Speeds Around 100 Bottles/Min

M6 Series Size Range 25-122mm Lay Flat

Band Lengths to 3”

Fast Changeover

Spacing Wheel for More Efficient Bottle Handling

MAX Bag Sealing and Printing Machine

From our low-cost manual load SX-Bagger to our standard semi-automatic MAXTM, or MaxPro24, these bagging machines are designed to the highest standards in the industry. These are the most dependable bagging machines in the business. Combined with in-line thermal imprinters and in-feed devices, we can deliver a total system that meets your packaging needs.

Standard Features and Options:

12” Color Touch Screen

Stepper Drive System

Height Adjustable Loading Area

203 DPI Zebra based on the ZT610 Zebra Print Engine

Retractable Load Plate

Height Adjustable HMI

Independent Bag Deflator & Mount

Bag Opening Assembly

Foot Switch

Seal Flattener

Controls Interface Relays Kit (AUX I/O) 10ft

Power Configuration for 110V Areas

Printer Control Box

Power Belt Conveyor

A Powered Belt Conveyor uses return rollers to run a conveyor belt along a smooth bed, thus allowing for the smooth transportation of many different load types. It can easily carry loose components and other materials that roller conveyors have a harder time transporting. Since the slider bed conveyor has few moving parts, it does not create much noise. The powered belt conveyor design also makes it useful for transporting loads on inclines and declines. Typical powered belt applications include inspection, transportation, and assembly line operations. They can be made custom to your desired height and length and have variable speed.

X1 Semi Automatic Stretch Wrapper 1

Features:

Available with Up to 300% Prestretch Gears

Adjustable Film Tension

Automatic Film Laser Cut-off

Film Brake Alarm

7” Siemens Touch Screen Control Panel

Steel Frame with Heavy Duty ABS Panels

CE Certified Safety Standard

1 Year Complete Warranty, 3 Years All Electrical Parts

Specifications:

Low Profile Stretch Wrapper for 15-25 Loads Per Hour

Turntable Speed: 0-13 RPM Adjustable

Turntable Drive: 1HP Chain Drive

Turntable Size: 65” Diameter

Turntable Support: Double Nylon Rollers

Load Capacity: 4,000 Lbs.

Load Height Max: 94”

Film Delivery System: 300% Prestretch

Film Width: 20”

Film Diameter Max: 9.5”

Power: 110V, 50/60 Hz, 10 Amps

Dimensions: L111” x W71” x H105”

Weight: 1,760 Lbs.

X1 Semi Automatic Stretch Wrapper 2

Features:

Available with Up to 300% Prestretch Gears

Adjustable Film Tension

Automatic Film Laser Cut-off

Film Brake Alarm

7” Siemens Touch Screen Control Panel

Steel Frame with Heavy Duty ABS Panels

CE Certified Safety Standard

1 Year Complete Warranty, 3 Years All Electrical Parts

Specifications:

Low Profile Stretch Wrapper for 15-25 Loads Per Hour

Turntable Speed: 0-13 RPM Adjustable

Turntable Drive: 1HP Chain Drive

Turntable Size: 65” Diameter

Turntable Support: Double Nylon Rollers

Load Capacity: 4,000 Lbs.

Load Height Max: 94”

Film Delivery System: 300% Prestretch

Film Width: 20”

Film Diameter Max: 9.5”

Power: 110V, 50/60 Hz, 10 Amps

Dimensions: L111” x W71” x H105”

Weight: 1,760 Lbs.

Predator SS LP Stretch Wrap System

Low Profile (LP) pallet wrapping machines are best suited for dry areas where the primary means of loading is with a pallet jack. These machines typically sit directly on the workspace floor and have a very low-profile turntable, typically less than 4 inches off the floor. With a ramp option, it is very easy to load the turntable with a pallet jack. Low profile stretch wrapping equipment can be moved easily to different areas by forklift but can only be lifted from the control end.

Predator XS Stretch Wrap System

The Predator XS is packed with more features that deliver more performance than any other stretch wrap machine in the market. Select Stretch gives you the ability to change the pre-stretch gears from 250% to 200% in less than a minute. The automatic film-cutting system saves the operator time by automatically cutting the film at the end of the wrap cycle. The Predator XS will wrap your product at the lowest possible cost with maximum performance.

Rotary Unscrambling Table

Rotary Unscrambling Tables sort round bottles to feed off the table in a single file. Rotary feed tables are distinctive from rotary accumulating tables by the distinctive overhead tooling which helps accomplish the task of sorting. All rotary unscramblers have variable speed drives which comes in handy especially if fed bottles need to have separation.

BMQVC-3 Vacuum Feeder

The BMQVC-3 Vacuum feeder uses a pneumatic vacuum as an energy source. It is suitable for particulate matter, powder materials, etc., and it can directly transport the material to the tablet press, mixer, granulator, and other equipment. This vacuum feeder is simple in structure and easy to operate, which can reduce workload and improve work efficiency

Features:

Feed Volume: 600 Kg/H

Bin Volume: 12L

Air Consumption: 720 L/Min

Dimensions: 950x600x1800

Weight: 150 Kg

BMP-S1 Desiccant Inserter

The BMP-S1 Packserter automatically separates desiccants, oxygen absorbers and other packets from continuous strips and inserts them into bottles or other containers at speeds of up to 100 packets per minute. A sensor array automatically finds the proper cut location between packets and makes sure the roll is in place, the packet is fed, and a bottle is present before allowing each cut and insertion. It’s easy to rely on the PS1 for consistent, unattended operation.

Features:

- Automatically cuts continuous strip packets into individual packets

- Suitable for any strip-type product such as desiccants, oxygen absorbers, lotion samples, fast-food condiments, etc.

- PLC controlled, with digital touch-pad operator interface

- Brushless DC step motor drive for repeatability and reliability

- Easy access, positive drive, belt feed mechanism

- Pneumatically operated knife assembly

- 3-color stack light (Green/Yellow/Red) for high-visibility status indication

- Automatic power feed on supply spool, for zero-tension

- Ready to roll up to any conveyor, includes lift platform and bottle-gating system

- Stainless steel, anodized aluminum, acetal & polycarbonate construction

Specifications:

- Product Capacity: 1/4-gram to 5-gram packets on continuous strip spool

- Spool Capacity: 11.8” wide x 3” ID core x 18.1” OD (30 x 7,5 x 46 cm)

- Rate: Up to 120 cut packets per minute, depending on length of packet

- Electric: 120 VAC, 5.0 Amp, 50/60 Hz

- Air: Supply pressure 50 PSI (344 kPa), consumes less than 1.0 CFM (28 LPM)

- Size: Adjustable 66 to 76” high x 20” wide x 30” Deep (168 to 193 x 51 x 76 cm)

- Weight: without product spool – 250 lb. (113 Kg)

- Footprint: 20” wide x 30” deep (51cm x 77cm)