Tube Filling Machines & Cartoners

We offer both semi-automatic and fully automatic tube filling machines for both plastic and metal tubes. For plastic tubes, you may choose from either Ultrasonic or Heat-Sealing machines. Our semi-automatic machines are hand loaded and are available in table-top single tube applications or larger 10 station turntable versions. Our automatic tube filling and sealing machines feed the tube into a rotary indexing table, orients the tube then fills and seals with either heat seal and trim, or fold and crimp for metal tubes. They are suitable for a wide range of applications, tube filling and sealing equipment can fill creams, lotions, food products, pharmaceuticals, greases, gels, glues, and pastes. All of our automatic tube filling and sealing machines include automatic tube loading, orientation, filling, sealing, and embossing for plastic or metal tubes with speeds ranging from 30 to 80 tubes per minute.

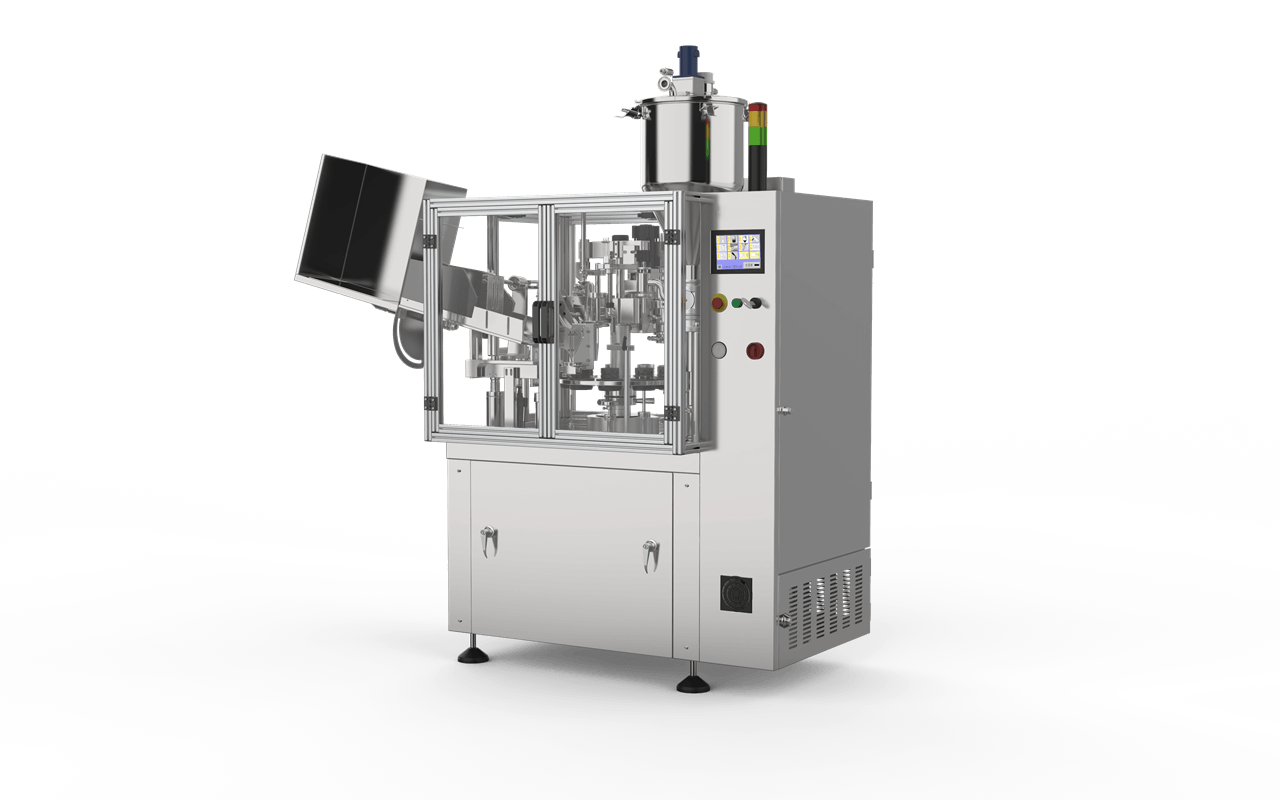

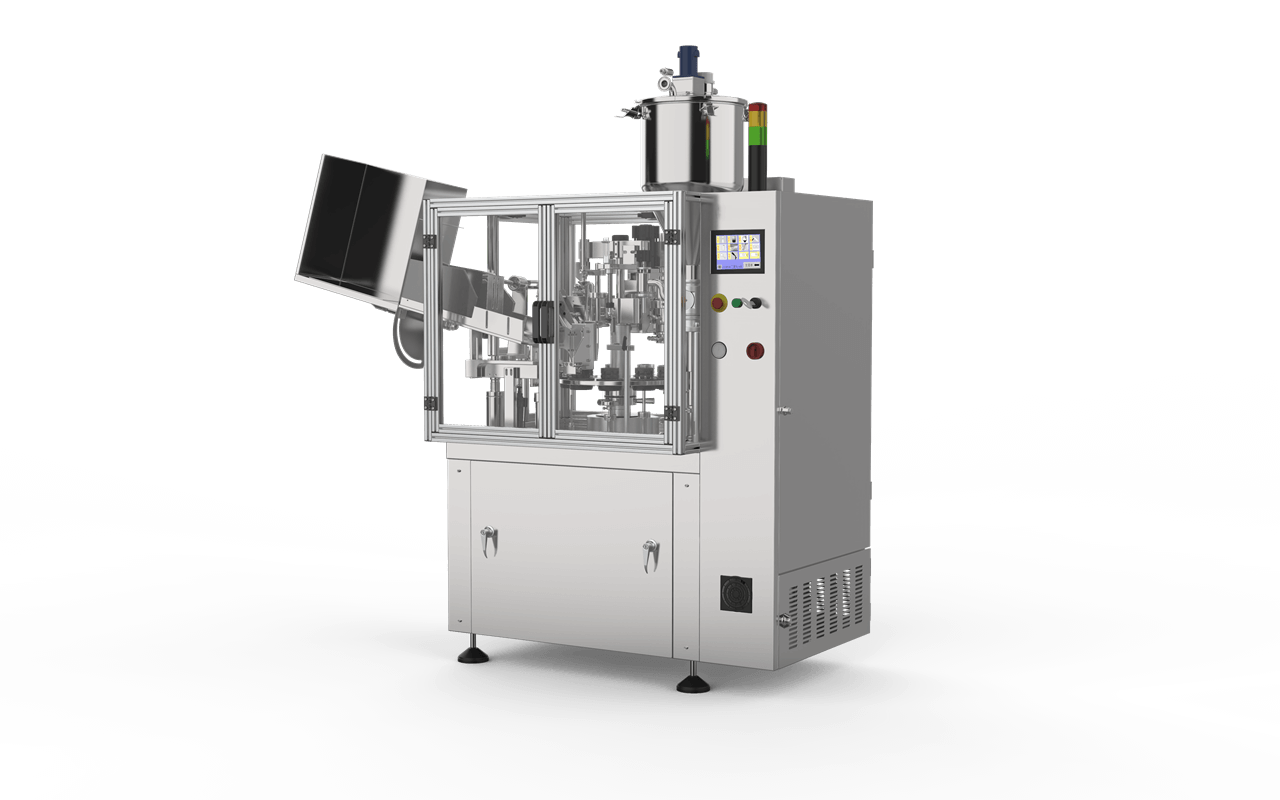

BMNF-30B Plastic Tube Filler and Heat Sealer

Widely used in pharmaceutical, food, cosmetic, and daily chemical industries to fill ointment or viscous fluid materials into plastic tubes or laminated tubes. And then seal the tube tails, trim the tails, and print (emboss) code on tubes automatically.

- Fulfills tube feeding, marking identification, filling, hot air sealing, trimming, code printing, and finished product ejection through an automatic control system.

- Adopts touch screen and PLC control system. Easy to operate.

- Tube feeding is conducted pneumatically via a vacuum device.

- Sense the color center by rotary and photoelectric inductance to position accurately.

- The material contacting part is made of 316L stainless steel, clean, sanitary and conforming to GMP standard requirements.

- Filling volume 5-250ml (tube)

- Filling accuracy ≤±1%

- Capacity 1800-2400 (tubes/hour Adjustable)

- Tube diameter ф10- 50mm

- Tube length 210mm (Max. Length)

- Hopper volume 40 L

- Power AC380/220V (Optional)

- Compressed Air 0.5-0.7MPa

- Hot air 3.0 kW

- Dimension 1900(L)×850(W)×1900(H)mm

- Weight (Approx) 850kgs

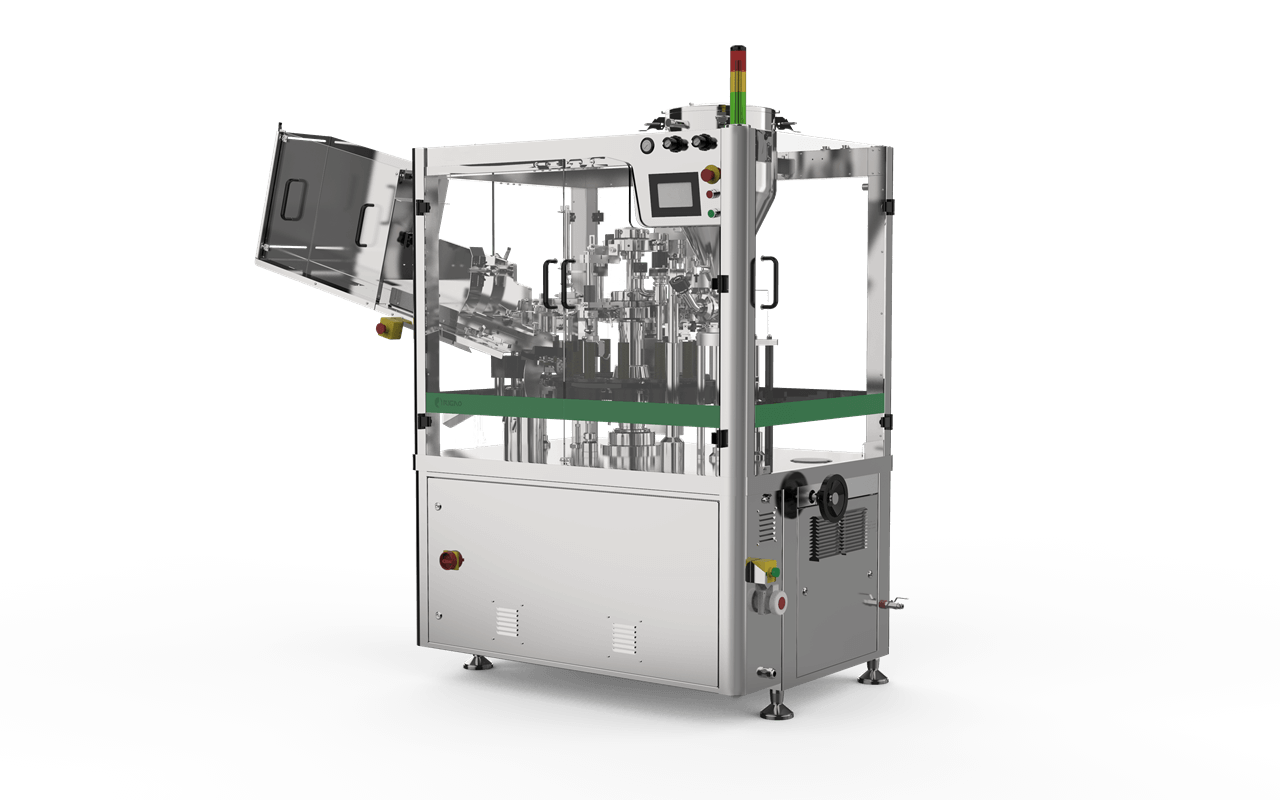

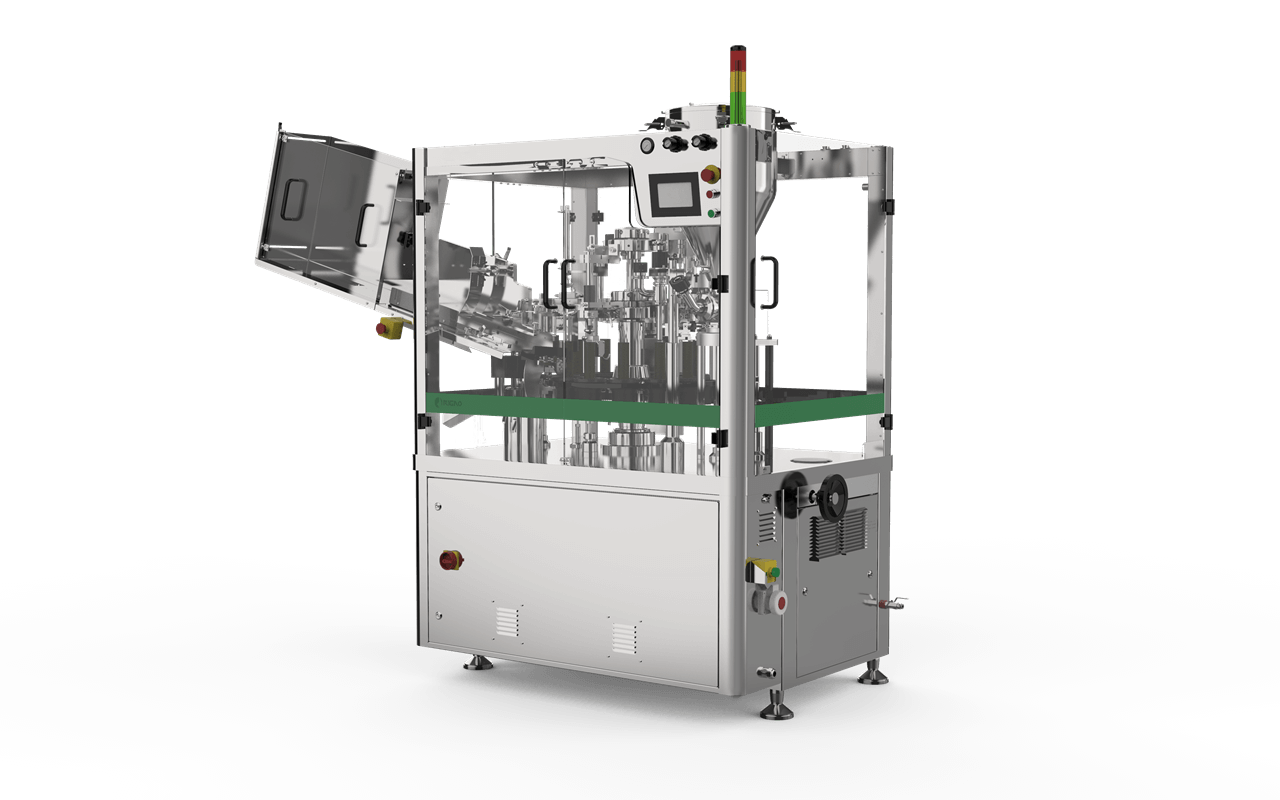

BMNF-80B High Speed Plastic Tube Filler and Heat Sealer

Automatic tube feeding and tube washing, marking identification, filling, hot air sealing, code printing (embossing) trimming, and ejecting out of the tube are conducted by a fully automatic control system.

- Tube washing and feeding are conducted pneumatically, accurate, and reliable.

- The materials contacting part is made of 316L stainless steel, clean, sanitary, and conforming to GMP for medicine manufacture.

- With safety device, the machine is shut down when the door is opened, and no tube filling. Overload protection is provided.

- Filling volume 5-250ml(tube)

- Filling accuracy ≤±1%

- Capacity 1800-4800 (tubes/hour Adjustable)

- Tube diameter ф10- 50mm

- Tube length 60-210mm (Max. Length)

- Hopper volume 40 L

- Power 380/220V (Optional)

- Dimension 2390×1140×2180mm LxWxH

- Weight (Approx) 1000kg

BMZF-60B Aluminum Tube Filler and Sealer

Aluminum Tube Filling and Sealing Machine can be used in pharmaceutical, food, cosmetic, and daily chemical industries to fill ointment or viscous fluid materials into aluminum tubes. It fold-seals the tube tails and can print batch numbers & production dates on tubes.

- Fulfills tube feeding, marking identification, filling, fold sealing, code printing, and finished product ejection through an automatic control system.

- Adopts touch screen and PLC control system. Non-contact operation. Easy to operate.

- Compact configuration. Automatic tube feeding. Fully-enclosed conveyer part.

- Tube feeding is conducted pneumatically via a vacuum device.

- Multiple edge folding ways. Can get a double fold, three-time fold or saddle-type fold on the same machine by adjusting or replacing the robot hand.

- Filling volume 5-150ml(tube)

- Filling accuracy ≤±1%

- Capacity 1800-3000(tubes/hour Adjustable)

- Tube diameter ф10- 32mm

- Tube length 185mm (Max. Length)

- Hopper volume 40 L

- Power 380/220V (Optional)

- Compressed Air 0.5-0.7MPa

- Power 2Kw

- Dimension 1900×850×1900mm LxWxH

- Weight (Approx) 850kgs

BMZF-80B High Speed Aluminum Tube Filling and Sealing Machine

Aluminum Tube Filling and Sealing Machine can be used in the industries of pharmaceutics, foodstuffs, cosmetics, and daily chemicals for smoothly and accurately filling all kinds of pasty and viscous fluid and materials alike, into metal tubes and then carrying out tube end folding, sealing, and lot number embossing.

- With a touch screen and PLC control system, it is convenient and reliable. Compact design and auto tube feeding.

- Tube washing and feeding marking identification, filling, folding, sealing, code embossing, and finished product output are all conducted automatically.

- Tube feeding is conducted pneumatically, accurately, and reliably.

- Filling volume 5-200ml(tube)

- Filling accuracy ≤±1%

- Capacity 1800-4800 (tubes/hour Adjustable)

- Tube diameter ф13- 40mm

- Tube length 75-210mm (Max. Length)

- Hopper volume 40 L

- Power 380/220V (Optional)

- Dimension 2390×1180×2140mm LxWxH

- Weight (Approx) 1500kgs

BMZHJ-70B Automatic Horizontal Cartoning Machine

RGZHJ-70B Automatic Horizontal Cartoning Machine completes the whole process of tube feeding, carton feeding, manual feeding, tube pushing, coding, carton folding, defective kicking, and finished products with the full-automatic operation system.

- The rotary grab mechanism can tilt grab the tubes to the main transmission positioning slot

- The process of box feeding adopts active carton opening, which makes the whole process of carton sucking, carton opening, and carton feeding more stable and reliable. Effectively solve the problem of carton opening due to dampness and deformation

- Folding is more stable, and folding box mechanism for independent box integrated design, more convenient adjustment, and shorter adjustment time.

- Product Dimension 65x30x25—240x95x80mm

- Manual Dimension (L×W) 100×20—200x50mm

- Capacity 1200-4200pcs/hour

- Power Supply 380/220V (Optional)

- Working Compressed Air 0.6-0.8MPa

- Air Consumption 350L/minute

- Electromotor Power 0.75Kw

- Dimension (LxWxH) 1.8Kw

- Dimension (LxWxH) 2750×1500×2180mm

- Weight 1000kg

BMSNF-15A Manual Plastic Tube Filling and Sealing Machine

The working process requires manual loading and consists of manual color-mark finding, filling, heating, sealing, manufacture date or lot code printing (embossing), cutting, and tube discharging.

- Filling volume 10-250ml(tube)

- Production capacity 300-700 tubes/hour

- Speed 15 tubes/minute

- Tube diameter ф10- 50mm

- Tube length 110-250mm (Max. Length)

- Tank capacity 25 L

- Electric current 15A

- Packing size 1000×1000×1400mm LxWxH

- Weight 135kgs

BUS-2020T Ultrasonic Tube Sealing Machine

The BUS-2020T is a manually loaded and unloaded tabletop ultrasonic plastic tube sealing machine only, with no filler. The high frequency vibration acts on the two surfaces of the plastic, and the heat generated by the vibration causes these two surfaces to be welded together tightly, the strength of the welding area is the same as other areas of the plastic. No need for adhesive or heating, It replaces the traditional hot pressing or bonding process. It is low cost with no pollution and no damage to plastic tubes. It is widely used in cosmetics, commodities, medicine, food, etc. Embossing on the seal is optional.

- Power Supply 220VAC, 50/60Hz, 2000W

- Frequency 20KHZ

- Tube Height 50-250mm

- Tube Diameter 10-50mm

- Speed 10-20 tubes/minute

- Dimensions 860x620x610mm

- Weight 70KG

BUS-2020TF Ultrasonic Plastic Tube Filling and Sealing Machine

The BUS-2020TF is a manually loaded and unloaded tabletop ultrasonic plastic tube filling and sealing machine. The high-frequency vibration acts on the two surfaces of the plastic, and the heat generated by the vibration causes these two surfaces to be welded together tightly, the strength of the welding area is the same as other areas of the plastic. No need for adhesive or heating, It replaces the traditional hot pressing or bonding process. It is low cost with no pollution and no damage to plastic tubes. It is widely used in cosmetics, commodities, medicine, food, etc. Embossing on the seal is optional. A heating and mixing hopper is also optional.

- Power Supply 220VAC, 50/60Hz, 2000W

- Frequency 20KHZ

- Tube Height 50-250mm

- Tube Diameter 10-50mm

- Filling Range 10-250ml

- Speed 10-20 tubes/minute

- Dimensions 860x620x1300mm

- Weight 95KG

BUS-2020TTF Semi Automatic Ultrasonic Plastic Tube Filler and Sealer and BUS-05FF Material Feeding Pump

The BUS-2020TTF is a manually loaded 10-station ultrasonic plastic tube filling and sealing machine. The high-frequency vibration acts on the two surfaces of the plastic, and the heat generated by the vibration causes these two surfaces to be welded together tightly, the strength of the welding area is the same as other areas of the plastic. No need for adhesive or heating, It replaces the traditional hot pressing or bonding process. Widely used in cosmetics, commodities, medicine, food, etc. Once a tube is hand-loaded the tube is oriented to the eye mark, and is filled, sealed, trimmed, and ejected down a chute into your box or tub. Embossing is optional, as is a heating and mixing hopper. The optional material feeding pump moves product from your barrel or tub to the machine’s hopper.

- Plastic or Laminated Tubes

- Power Supply 220VAC, 50/60Hz

Power 2000W - Frequency 20KHZ

- Tube Height 50-250mm

- Tube Diameter 10-50mm

- Filling Range 10-250ml

- Speed 10-30 tubes/minute

- Dimensions 1100x900x1750mm

- Weight 300KG

BUS-2020TTFF Automatic Ultrasonic Plastic Tube Filler and Sealer

The model BUS-2020TTFF has a tube hopper and is an automatically loaded 10-station ultrasonic plastic tube filling and sealing machine. The high-frequency vibration acts on the two surfaces of the plastic, and the heat generated by the vibration causes these two surfaces to be welded together tightly, the strength of welding area is the same as other areas of the plastic. No need for adhesive or heating, It replaces the traditional hot pressing or bonding process. It is widely used in cosmetics, commodities, medicine, food, etc. Once a tube is automatically loaded from the hopper, the tube is oriented to the eye mark and is filled, sealed, trimmed, and ejected down a chute into your box or tub or onto a conveyor. Embossing is optional, as is a heating and mixing hopper. An optional material feeding pump moves product from your barrel or tub to the machine’s hopper.

- Plastic or Laminated Tubes

- Power Supply 220VAC, 50/60Hz

Power 2000W - Frequency 20KHZ

- Tube Height 50-250mm

- Tube Diameter 10-50mm

- Filling Range 10-250ml

- Speed 10-30 tubes/minute

- Dimensions 1100x900x1750mm

- Weight 300KG

BUS-MC200 Semi Automatic Aluminum Tube Filling and Sealing Machine

The BUS-MC200 is set to 16 stations. Manually insert a tube into the holder on the dividing aluminum plate and use the machine to drive the translocation. Photoelectric detection (filling with tube, not filling without tube) is carried out for quantitative filling of metering pump, sealing, and printing at one time. The finished product is automatically released after sealing. It is widely used in medicine, daily chemicals, food, pigment, fine chemical industry and other industries such as ointment, skin cream, hair dye, shoe polish, toothpaste, etc.

- Aluminum Tubes

- Power Supply 220VAC, 50/60Hz, 1500W

- Gas Source (Mpa) 0.6-0.8

- Accuracy ±1%

- Tube Diameter 10~50mm

- Filling Range 20-200ml

- Speed 10-50 tubes/minute

- Dimensions 1140x750x1630mm

- Weight 350KG

BMZ-160 CARTONER MACHINE

The BMZ-160 is a high-speed automatic cartoning machine designed for efficient packaging. It handles product feeding, box retrieval, opening, product insertion, edge folding, sealing, and final package output. Constructed from durable stainless steel, it adheres to pharmaceutical industry standards. With overload protection and a user-friendly control system, it ensures reliability and operator safety. The machine integrates a photoelectric eye detection system, offers easy adjustment for various sizes, and can be customized with additional features. It can also be integrated with other equipment for joint production. The NHZ-160 provides automation, versatility, and ease of use in packaging processes.

Features:

- The machine features automatic box feeding, opening, product insertion, edge folding, and box sealing, all in a compact and user-friendly design.

- It utilizes a servo/stepper motor, touch screen, and PLC programmable control system, with a clear and simple man-machine interface for enhanced automation and ease of operation.

- The photoelectric eye automatic detection and tracking system ensures that no box is picked up without a product infeeding, resulting in maximum savings of packaging materials.

- The machine offers a wide packaging range and easy adjustment, allowing for rapid changeover between various specifications and sizes without the need for parts replacement.

- Specifications can be changed without replacing the parts, requiring only adjustments.

- The machine is equipped with automatic shutdown and main drive motor overload protection when there is no product or when the product supply is not in place, ensuring safety and reliability.

- It provides an automatic display of packing speed and packaging quantity counting for convenient monitoring.

- Optional top turn-type safety protective cover can be used based on customer requirements, providing easy operation and an attractive appearance.

- It can be seamlessly integrated with other equipment such as flow pack packaging machines, bottle lines, filling machines, labeling machines, jet coding machines, online weighing meters, and other production lines, allowing for joint production.

- Various automatic feeders and box loading systems can be designed to meet specific packaging requirements. Additionally, a hot melt glue machine can be incorporated for hot melt glue spray sealing of boxes, based on customer requirements.

Specifications:

Packing Speed: 20-40 Boxes/Min

Paper Box Requirements: 250-400g/m2

Box Range of Sizes: L (250-300) x W (35X60) x H (35-60)

Gas Pressure: ≥0.6Mpa

Gas Consumption: 20m3/h

Power: 220V, 60Hz, 1.5Kw

BUS-50AL Semi Automatic Tabletop Aluminum Tube Filling and Sealing Machine

The BUS-50AL Semi-auto Tabletop Aluminum Tube Filling and Sealing Machine is suitable for ointment, gooey products, AB Glue, super glue, epoxy glue, skin oil, and hair dye. Our Tube Filling and Sealing machine is used for filling liquid or cream into aluminum tubes with a single fold at the tube’s end. It is widely used in the packing of pharmaceutical, cosmetic, food, and chemical industries. It also includes embossing on the tube end.

Features:

- Manually Loaded

- 1 Tube Station

- Includes 1 Tube Holder for 1 Diameter Tube

(Extra Tube Holder Required for Each Additional Diameter Tube) - Sealing Type: Single Fold

- Speed: 10-30 Tubes/Min

- Tube Diameter: 16-50mm

- Tube Height: 80-250mm

- Filling Range: 10-120ml, 30-500ml

- 8-10 Digit Embossing on Tube End

- Power: 220V, 60Hz, 4500W

BM-50C 16 Station Semi-Automatic Aluminum Tube Filling Sealing Machine

The BM-50C 16 Station Semi-auto Tabletop Aluminum Tube Filling and Sealing Machine is suitable for ointment, gooey products, AB Glue, super glue, epoxy glue, skin oil, and hair dye. Our Tube Filling and Sealing machine is used for filling liquid or cream into aluminum tubes with a double fold at the tube’s end. It is widely used in the packing of pharmaceutical, cosmetic, food, and chemical industries. It also includes embossing on the tube end.

Features:

- Manually Loaded

- 16 Tube Stations

- Includes 16 Tube Holders for 1 Diameter Tube

(Extra Tube Holder Set Required for Each Additional Diameter Tube) - Sealing Type: Double Fold

- Speed: 10-40 Tubes/Min

- Tube Diameter: 10-50mm

- Tube Height: 50-250mm

- Filling Range: 5-50ml

- 8-10 Digit Embossing on Tube End

- Power: 220V, 60Hz, 1500W

- Gas Source (Mpa): 0.6-0.8